Since 1880 Horgenglarus has made furniture using time-houred techniques. That's why its classic. sturdy chairs are still in high demand in the Alpine nation, used by both parliament and the general public, and have become byword of Swissness. Monocle, 2011

Horgenglarus factory in the town of Glarus.The factory sits at the base of the Linth Valley in the shadow of the imposing Glärnisch mountain.

Haefeli II model in natural chestnut with leather seat. Designed in 1926 by architect Max Haefeli.

Seat reinforcements for the front of the chairs

Employees at work in the upholstery department. The women still work on decades-old sewing machines to stich together seat covers from leathers sourced from Swiss tanneries.

Founded in 1880, Horgenglarus may not be a household name beyond the country's borders, unlike Rolex or Roche, but the company's wooden sturdy chairs can be found in every corner of the multilingual confederation from St Moritz hotels to Zürich's legendary Kronenhalle restaurant.

“We take pride in not outsourcing our work,” says Markus Landolt, who runs furniture maker Horgenglarus.

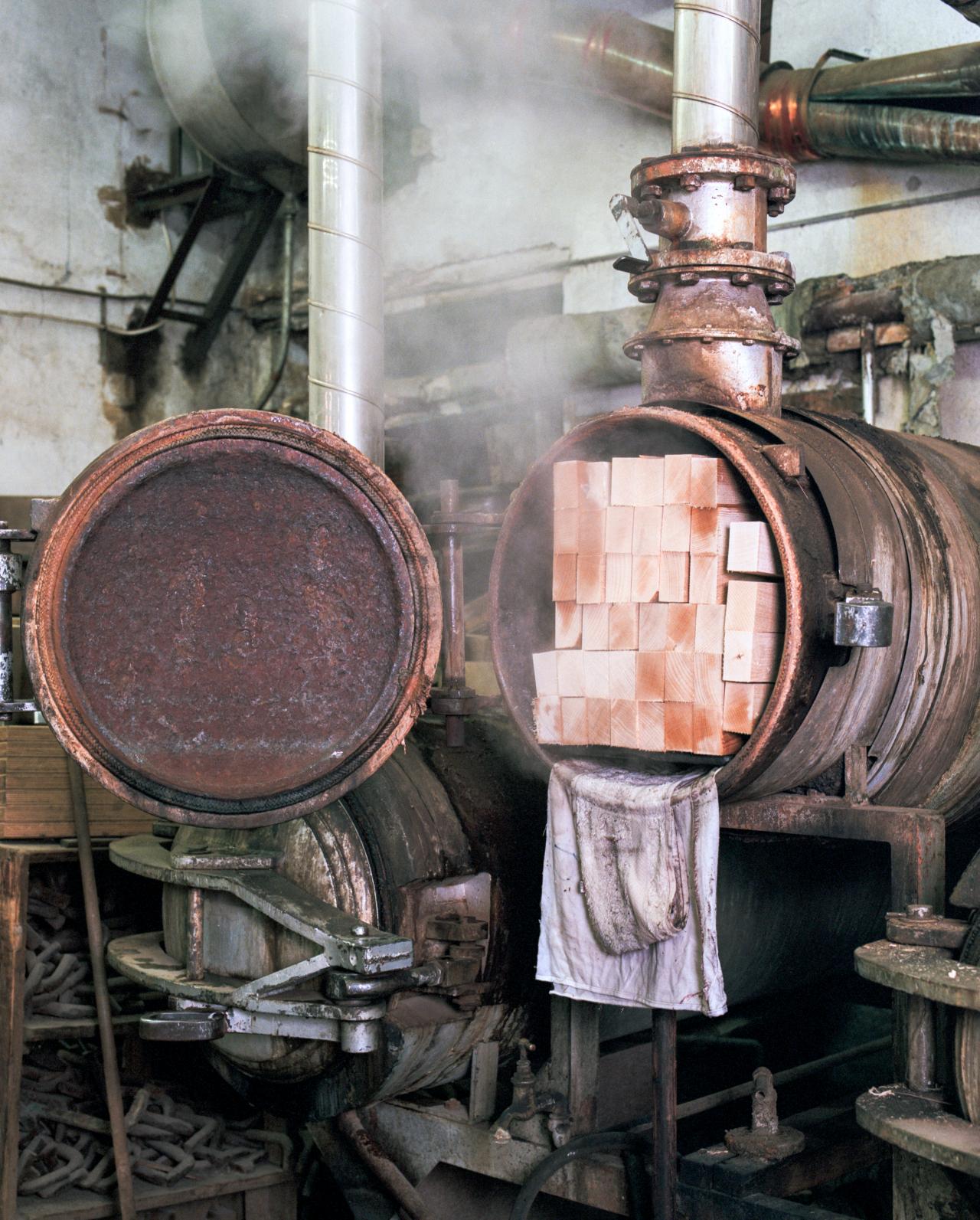

Wood being steamed in the bending workshop. Inside 1940s-era metal containers that resemble torpedo tubes, strips of wood are steamed at temperatures up to 100C to make them pliable. “It's a century-old craft you rarely see today,”explains Landolt.“

Carpenter prepares to saw and plane a board. Raw materials are sourced from the Jura mountains and hand-selected in the forest to ensure the company gets the best trees.

Wood planks in the mill

"Horgenglarus is a Swiss icon that nobody knows, even if everybody has sat on them before." Michael Sarp, CEO Nordeck-Group

Chairs awaiting assembly

Unfinished Lyra chairs awaiting assembly

In the assembly room back and seats are joined.

Each year, the team of 45 craftmen and craftwomen are able to build 18,000 chairs and tables. On average, a chair takes four weeks to assemble.

Stacks of chairlegs

Staff drill holesone by one to attach legs unto the frame and then secure them with glue and screws, stopping repeatedly to check the fit.

Stacks of armrests

In a world of round-the-clock manufacturing and global supply chains, Horgenglarus only builds to order, they don't stockpile. Mass production is not part of their vocabulary.

Classic models in the paint shop

In the paint studio the workers apply at least three layers of lacquer, pausing to sand the surface by hand after each coating and leaving the chairs to sit overnight.

Miro models without armrests in cherrywood and beech. Designed in 1999 by Hannes Wettstein.

Prova, solid wood dining table in oak or cherrywood. Designed in 2010 by Heinz Baumann.

Chairlegs ready to be mounted. Horgenglarus chairs cost between €400 - €650 each. But what you get is a product that is well made and that will last a very long time.